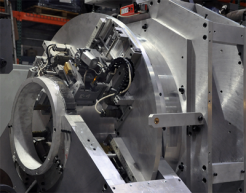

FLUX LEAKAGE ROTARIES

ROTARIES

Magnetic Flux leakage (MFL) non destructive test systems accurately detect defects in heavy-wall magnetic tubing, including oil country tubular goods (OCTG), bars, and parts. Systems are available in sizes to handle up to 500 mm diameter and 19 mm wall thickness tubes. Transverse and Longitudinal rotaries detect surface defects as small as 5% on OD and 5% on the ID as well as defects within the wall, depending on material type and condition can be detected.

ROTOFLUX® ELECTRONICS

The electronics are capable of differentiating between ID and OD defects, using a unique multiprobe feature which allows convenient operation at greater speed. A flux measurement circuit is included to indicate whether the test piece is properly saturated. To detect longitudinal defects, the material under test is driven through rotating headplates that include transverse magnetizing coils and test probes.MAC also offers Rotoflux systems to detect transverse defects where the magnetizing poles are placed in a fixed position perpendicular to the axis of the material under test, and the sensors are rotated around the test piece.