NDT in Oil and Gas Industry

Types of Oil & Gas Products include:

- Line Pipe- (Larger diameter, relatively thin wall)

- Drill Pipe- (Typically heavy wall seamless tubes)

- Casing – (Mainly seamless but may be welded)

- Sucker Rods- (In Cut lengths)

- Umbilical Coils- (Small diameter, long length)

- Other types of tubes- (Including coupling stock)

Note: Line pipe, drill pipe, casing, and other types of oil and gas tubes are best inspected using flux leakage & ultrasonic multi test systems. Whereas, sucker rods and umbilicals are best inspected using eddy current & ultrasonic multi test systems.

Common Applications Include:

- Sour Gas

- High Pressure

- Offshore Wells

- Arctic Wells

- API grades for other wells

Methods of Production Include:

- Welded- (Scarfed & Annealed for flux leakage)

- Seamless

Inspecting Oil Country Tubular Goods (OCTG)

With over 85 years of experience, MAC has a wide variety of custom designed systems for the inspection of oil country tubular goods (OCTG) and other oil and gas products that not only meet individual client specifications, but that of API 5CT and 5L, ASTM, and ISO.

MAC’s highly trained and knowledgeable engineers, field staff, and representatives provide superior NDT equipment, services, and training worldwide.

MAC’s Rotoflux® flux leakage and Echomac® ultrasonic inspection systems are the best suited for inspecting heavy wall pipe for wall thickness variations, laminations, longitudinal, transverse, ID/OD, and internal defects. These rotary systems are designed to inspect pipe up to 500mm in diameter.

MAC eddy current systems such as the Multimac® and the Minimac® 40 are also available for thinner wall pipe.

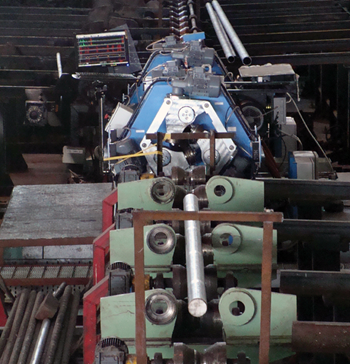

mage above is an inline ultrasonic rotary test system designed to test carbon steel tubes for longitudinal and transverse defects as well as wall thickness and lamination. The system includes the seal-less designed ultrasonic rotary mechanics developed to minimize maintenance especially due to dirt accumulation from hot rolled product. Coupled with the rotary is the Echomac® electronics which provides all the channels necessary in one computer cha

ssis. The rotary head is mounted on a Triple Guide Roll Test Bench which is highly automated to provide fast changeover times and consistent product throughput, and is extremely durable; thus able to withstand the heavy demands of OCTG plant conditions.

The combination of an ultrasonic and eddy current NDT system allows for the detection of incomplete and mismatch welds, pinholes, leakers, and weepers in small diameter, long length umbilical coils. For sucker rods, which are hot rolled, cut length carbon or alloy steel, complete automated systems including encircling and spinning probe eddy current for surface and near surface defects, and ultrasonic rotary for internal and subsurface defects are available.